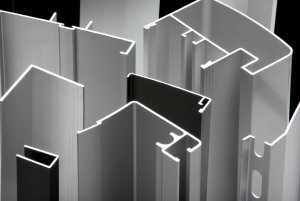

What Are the Specifications and Accessories of Architectural 【Aluminum Extrusions for Doors and Windows】?

In the architectural market, aluminum doors and windows have become standard for both residential and commercial buildings. Among them,【aluminum extrusions for doors and windows】 play a crucial role. These extrusions serve not only as the structural backbone but also directly influence the appearance, strength, airtightness, water resistance, and weather durability of the doors and windows. This article introduces common specifications, necessary accessories, and pricing models of aluminum extrusions for doors and windows to help homeowners, architects, and engineers gain a clear understanding of their application and cost.

What Are the Specifications of Aluminum Extrusions for Doors and Windows?

The specifications of 【aluminum extrusions for doors and windows】 vary based on different window and door systems—such as casement windows, airtight windows, sliding doors, and floor-to-ceiling aluminum alloy windows. The most fundamental differences come from the profile cross-section design.

Common specifications include:

- Profile thickness: Common thicknesses include 1.2mm, 1.5mm, 2.0mm, 2.5mm, and even up to 3.0mm for industrial or explosion-proof doors and windows. The thicker the material, the stronger and more expensive it is.

- Aluminum grade: Typically uses 6063-T5 aluminum alloy, which offers good extrudability and weather resistance, conforming to CNS national standards.

- Surface treatments: Includes anodizing, powder coating, electrophoresis, and wood grain transfer. Among these, anodizing is most common due to its corrosion resistance and color stability.

Key Characteristics:

- Lightweight yet strong: Aluminum has a low density but high strength, ideal for architectural framing.

- Excellent corrosion resistance: Treated surfaces can withstand Taiwan’s humid and hot climate.

- High airtightness and water resistance: When combined with high-quality seals and frames, it effectively prevents wind and water infiltration.

- High flexibility in design: Aluminum extrusion allows custom cross-sectional shapes for different window designs.

Processing steps:

- Aluminum billet preheating

- Die assembly

- Extrusion molding

- Cutting

- Heat treatment

- Surface treatment

- Quality inspection and packaging

This process requires high-precision equipment and mold design to produce profiles that meet structural strength and accuracy standards.

Advantages summary:

- Durable and resistant to deformation

- Recyclable and suitable for reprocessing

- Modern appearance suitable for contemporary architecture

- Easy to repair and replace

What Accessories Are Required for Aluminum Extrusions for Doors and Windows?

To ensure a complete and functional door and window system, accessories must be integrated alongside the extrusions to achieve airtightness, water resistance, soundproofing, and security.

Common accessories and functions:

- Sealing strips (airtight and watertight seals):

- Materials: EPDM, TPV, silicone

- Function: Prevent rain infiltration and air leakage

- Features: Elastic, weather-resistant, high bonding with aluminum

- Extrusion shapes: H-type, P-type, O-type

- Rollers and sliding tracks:

- Used in sliding windows and doors for load-bearing and smooth operation

- Materials: Stainless steel, nylon, aluminum alloy wheel frames

- Tracks: Grooves are pre-designed in the extrusion for precise installation

- Window hardware (hinges, locks, handles):

- Functions: Smooth operation, anti-theft, anti-pinch, positioning

- Materials: Zinc alloy, stainless steel, aluminum alloy

- Must be rust-proof, durable, and precisely installed

- Soundproofing materials:

- Such as double-glazed glass, laminated glass, acoustic cotton

- Structure like 5+9A+5mm with reinforced extrusions can reach 30–40dB soundproofing

- Glass clamps and glazing beads:

- Secure the glass panels and support the structure

- Inserted into the extrusion design using embedded clips or screws

Summary of features and advantages:

- Accessories must precisely match extrusion profiles to ensure safety

- Must be weather-resistant, corrosion-proof, and deformation-resistant

- Modular components improve maintenance flexibility and modern aesthetics

Work with Professional Suppliers to Ensure Quality and Cost-Efficiency

When it comes to door and window projects, aesthetics are only part of the equation. Structure, safety, soundproofing, and long-term durability matter more. The key to achieving these qualities lies in selecting reliable, high-quality 【aluminum extrusions for doors and windows】 combined with professional design and the right accessories.

If you’re working on product design, equipment development, or architectural planning and need support for custom dies, co-extrusion, hybrid processing, or surface treatments, don’t hesitate to contact 【Yuan-Cheng Aluminum Co., Ltd.,】for assistance. With extensive experience in extrusion system planning, precision machining, and finishing technologies, we offer mold design, custom profiles, OEM services, and on-site support—making us your most trusted partner in aluminum door and window engineering.

contact us