Outdoor vs. Indoor 【Aluminum Louvers】(Louver Doors): Styles and Sizes Explained

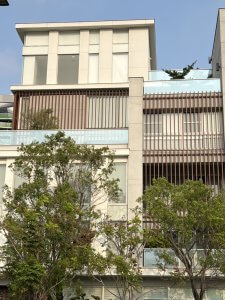

As architectural design increasingly emphasizes both aesthetics and functionality, Aluminum louvers have gradually evolved from industrial applications to become a popular material in residential and commercial spaces. With their sleek appearance, lightweight structure, and versatile functionality, aluminum louvers have become a favored choice for architects and designers. Whether used for luxury home façades, garage doors, balcony sunshades, or interior partitions and ceiling features, aluminum louvers can blend seamlessly with various styles~~creating spaces that balance ventilation, lighting, and privacy.

In Taiwan’s humid and rainy climate, traditional iron structures are prone to rust, and wooden materials are easily deformed by moisture. Aluminum, however, stands out with its lightweight, weather-resistant, anti-corrosive, and recyclable properties~making it the top choice for modern architects and interior designers. With the growing popularity of green building and energy-saving concepts, aluminum louvers have proven to be an ideal material for shading, heat reduction, and improved ventilation, aligning perfectly with low-carbon and eco-friendly construction trends. They have become indispensable in both public infrastructure and residential renovation projects.

From a professional perspective, this article explores the design differences, common styles, size specifications, and processing technologies of outdoor and indoor aluminum louvers, while analyzing three key factors that define their success in modern architecture~features, manufacturing process, and advantages. Through practical applications and installation experience, you will gain a clear understanding of how to select the right aluminum louver specifications and finishes for different environments.

Characteristics and Application Differences of Aluminum Louvers

In today’s architectural and interior design landscape, aluminum louvers have become one of the most sought-after metal materials in the Taiwanese market. Their popularity stems from their excellent ductility, structural stability, and adaptable design. The key lies in the material itself~aluminum is lightweight, corrosion-resistant, weatherproof, rust-free, and maintains its shape over time. It can also be customized in size and color according to project requirements.

-

Adaptation to Taiwan’s Climate

In Taiwan’s hot and humid climate, traditional iron easily rusts, wood decays, and plastics become brittle. Aluminum, with its stable chemical properties and recyclable nature, gradually replaces traditional materials as the mainstream choice. Architects and designers favor aluminum louvers for their ability to create a modern and layered visual effect~using different spacings, angles, and surface treatments to manipulate light, shadow, and privacy.

-

Indoor vs. Outdoor Types

Aluminum louvers can generally be classified into indoor and outdoor types:

- Indoor Type:

Indoor aluminum louvers often use anodizing or wood grain transfer techniques to enhance texture and aesthetics. They are widely used in ceiling designs, entry partitions, and wall dividers, where ventilation and appearance are priorities. - Outdoor Type:

Outdoor aluminum louvers are typically treated with powder coating or fluorocarbon coating, offering strong resistance to ultraviolet exposure and acid rain. They are commonly used for building façades, balcony shades, louver doors, or garage gates~where durability, rust resistance, and safety are crucial.

The main structural differences between the two types lie in thickness, surface coating, and mounting methods.

-

Common Sizes and Flexibility

Aluminum louvers offer great flexibility in size and specifications. Common profile widths range from 30mm to 200mm, with thickness varying by application. For large façades or garage doors, 2.0mm or thicker industrial-grade aluminum profiles are recommended. For ceilings or decorative wall panels, 1.0mm to 1.5mm lightweight profiles are sufficient.

This adaptability allows aluminum louvers to meet the needs of luxury residences, office buildings, and boutique homestays~offering a high degree of design freedom and practicality.

Manufacturing Process and Surface Treatment Technologies

The quality and lifespan of aluminum louvers depend not only on the grade of aluminum used (such as 6063 or 6061 alloys) but also on their manufacturing process and surface treatment. In Taiwan’s aluminum extrusion industry, professional manufacturers like YCAL Aluminum Industry provide complete production lines~from extrusion, cutting, surface finishing, and coating to final assembly—ensuring precision and consistent quality at every stage.

-

Extrusion and Forming

Aluminum billets are first heated and extruded through specialized molds to form profiles of specific cross-sectional shapes. This process determines the structural rigidity and design aesthetic of the louvers. With today’s advanced mold technology, a variety of widths, thicknesses, and joint structures can be produced for quick assembly and superior stability.

-

Cutting and Welding

After extrusion, aluminum profiles are precisely cut to the required installation dimensions. For larger louver doors or fences, welding may be necessary. High-precision TIG or MIG welding ensures flat, strong joints without deformation.

-

Surface Treatment and Anti-Corrosion Coating

Proper surface treatment is essential for durability and appearance. Common methods include:

- Anodizing – enhances corrosion resistance and adds a metallic luster; ideal for indoor applications.

- Powder Coating – provides weather resistance and offers a wide range of colors.

- Fluorocarbon Coating – designed for outdoor exposure; offers superior UV and acid rain resistance.

- Wood Grain Transfer – gives aluminum a natural wood appearance while maintaining strength and longevity.

Taiwan’s harsh climate places high demands on coating performance. Poor surface treatment can lead to oxidation, peeling, or discoloration over time. Professional manufacturers adjust coating thickness and baking temperature based on the intended use, ensuring a product lifespan exceeding 10 years.

-

Quality Control and Installation

Before delivery, each product undergoes dimensional inspection, adhesion testing, and salt-spray resistance tests. During installation, louvers can be mounted using concealed clip systems or screw-fastened assemblies, ensuring both efficiency and aesthetic cleanliness. Incorporating LED strips or shading blades can further enhance architectural style and functionality.

Advantages and Application Examples

Compared to traditional ironwork or PVC panels, aluminum louvers offer a unique combination of beauty, strength, lightness, durability, and eco-friendliness, making them an essential material in modern architecture.

-

High Structural Strength and Safety

Aluminum alloys provide excellent tensile strength and rigidity, effectively resisting impact and wind pressure. Louver doors prevent intrusion and deformation, while reinforced frames and hinge structures further improve security.

-

Weather Resistance and Easy Maintenance

One of the greatest advantages of aluminum louvers is their low maintenance requirement. Unlike iron structures that require periodic repainting, aluminum louvers maintain their appearance with simple water cleaning. Fluorocarbon-coated surfaces retain their color and gloss even after years of UV exposure.

-

Aesthetic Versatility and Design Flexibility

Aluminum louvers can be customized into vertical, horizontal, diagonal, or curved patterns, with finishes such as wood grain, matte black, champagne silver, or iron gray. Whether for minimalist architecture, industrial-style offices, or Japanese-inspired gardens, aluminum louvers integrate perfectly. Designers also use light and shadow interplay to turn louvers into architectural art.

Eco-Friendly and Recyclable

As a recyclable metal, aluminum supports sustainable construction with minimal environmental impact. It aligns perfectly with Taiwan’s green building and low-carbon material trends.

-

Common Applications

- Outdoor Louver Doors: for gates or garages—providing ventilation and privacy.

- Façade Panels: to reduce solar heat gain and improve energy efficiency.

- Balcony Fencing: combining safety and style.

- Indoor Partitions or Ceilings: enhancing spatial depth and airflow.

With its exceptional properties, refined production quality, and diverse applications, the aluminum louver has become a defining material in Taiwan’s architectural fusion of beauty and function. Whether for indoor decoration or outdoor protection, Aluminum louvers can express a range of styles through thoughtful design and precise fabrication.

If you are uncertain about size specifications, profile selection, or surface finishing, it is best to consult a professional extrusion manufacturer with proven expertise and engineering experience. From custom mold development and hybrid extrusion to multi-process finishing,

development, co-extrusion, composite processing, or surface treatment, please feel free to contact【Yuan-Cheng Aluminum Co., Ltd.,】 for professional service. ~ your trusted partner providing integrated aluminum louver solutions tailored to Taiwan’s climate and architectural needs.

contact us