Why Do OA System Office Furniture Use Aluminum Extrusions? A Complete Guide to Durability and Structural Advantages

Why has modern OA system office furniture fully shifted toward aluminum extrusions? It all begins with real market needs. In commercial offices, co-working spaces, tech companies, and even small to medium-sized businesses undergoing renovations, one of the most discussed topics is how to select office furniture that is flexible, durable, and quick to install. Especially in recent years, as work models evolve rapidly, companies must prioritize aesthetics, systematic cable management, long-term structural stability, and overall durability. Combined with rising office space costs and the need for flawless construction, businesses and designers have realized an important truth: traditional wooden, steel, or plastic-steel furniture can no longer meet the demands of modern work environments.

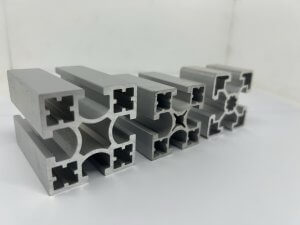

Under this shift, aluminum extrusions have gradually become the mainstream structural material for office furniture~especially within OA system office furniture. This rise is not only due to their sleek and modern appearance, but also because aluminum extrusions provide superior internal strength, structural design flexibility, and modular expandability. They are lightweight, resistant to deformation, capable of bearing heavy loads, and easy to relocate or reconfigure. These advantages significantly extend service life and improve durability~key factors for any commercial workplace.

The market also values efficiency and construction speed. Since office renovations must be completed quickly after building handover, aluminum extrusions~known for fast installation, minimal dust, and reduced wet construction~have become a preferred choice among contractors. With ESG becoming increasingly important, aluminum’s recyclability and low environmental impact also help companies meet sustainability requirements.

Ultimately, aluminum extrusions dominate this sector not because of aesthetics alone, but because of their material properties, manufacturing precision, structural advantages, and modular adaptability~capabilities that wood and steel cannot simultaneously offer. Taiwan’s aluminum extrusion industry possesses a fully integrated supply chain, from mold design, extrusion, production, machining, surface finishing, to assembly. This ensures high-quality, durable, and upgradeable system furniture solutions for companies.

Material Advantages of Aluminum Extrusions in Office Furniture: Why It Outperforms Wood and Steel

The rise of aluminum extrusions is no coincidence. Their inherent material properties align perfectly with the needs of contemporary office environments. From strength and weight to weather resistance and design flexibility, each factor directly affects furniture durability and performance~especially in Taiwan’s humid, temperature-shifting, and earthquake-prone environment.

-

Lightweight but High Strength: The Core of System Furniture

Aluminum is one-third the weight of steel, yet through extrusion and structural slot design, its rigidity can match~or exceed~thin steel components.

- Wood easily warps in humidity

- Steel rusts and welded joints become brittle over time

- Plastic-steel lacks structural strength

Aluminum extrusions provide a “light but strong” framework ideal for desks, partitions, shelves, and workstation structures.

-

Exceptional Weather Resistance for Taiwan’s Climate

With Taiwan’s high humidity, frequent rain, and large temperature variations, wood expands and cracks, and steel oxidizes easily.

Aluminum treated by anodizing or powder coating:

- does not rust

- does not absorb moisture

- maintains appearance for over 10 years

It retains a clean, modern look long-term without discoloration or corrosion.

-

Superior Modularity: Easily Removable, Adjustable, and Expandable

System furniture’s biggest advantage is flexibility. Aluminum extrusions allow:

- office relocation without damage

- fast expansion when new employees join

- simple reconfiguration of cable channels and IT setups

Wood and welded steel lack this adjustability.

-

High Structural Stability Over Time

Wood ages, plastic-steel becomes brittle, and steel corrodes.

Aluminum’s molecular stability means:

- long-term load bearing

- resistance to fatigue

- sustained rigidity

Perfect for desktops, monitor arms, filing cabinets, and partition frames.

-

Modern Aesthetic for Corporate Identity

Aluminum’s clean, minimal lines~paired with glass, veneer, or laminate~match the image of tech firms, finance companies, and co-working spaces seeking a professional, unified visual style.

How Aluminum Extrusion Processing Determines Furniture Quality

Aluminum extrusion’s popularity stems from its capability for precise engineering. Every step~from mold design to extrusion and CNC machining~directly impacts the final structural integrity.

-

Mold Design: The Foundation of Structural Rigidity

Each line, slot, and cavity within the mold determines:

- vertical load capacity of desk legs

- bending strength of beams

- modular compatibility of partitions

- cable routing space within workstation frames

Precision molds ensure tight assembly and prevent wobbling.

-

Extrusion Process: The First Gate of Material Quality

The extrusion process includes:

- heating 6000-series aluminum billets

- pushing material through the mold

- water/air cooling

- T5 or T6 heat treatment

This ensures:

- no internal voids

- uniform density

- consistent surface quality

- dimensional stability

Low-quality extrusions cause gaps and instability, which is why many brands specify Taiwanese-made aluminum.

-

CNC Machining: Precision Determines Stability

CNC accuracy directly affects:

- hole alignment

- screw depth

- joinery angles

- cut precision

Even minor deviations cause tilted desktops or unstable frames.

-

Surface Finishing: Critical to Durability and Appearance

Common treatments:

- anodizing

- powder coating

- wood grain transfer printing

They improve both aesthetics and protection, particularly abrasion resistance for high-touch OA furniture.

-

Assembly Engineering: The Beauty of Modular Aluminum Furniture

Compared to wood and welded steel, aluminum furniture uses:

- T-slot nuts

- angle brackets

- T-bolts

- fastening systems

Advantages:

- can be disassembled 20–30 times

- modular and reusable

- easy maintenance

- high structural stability

Which OA Furniture Components Use Aluminum?

-

Desks and Workstations

- Desk frame and under-structure

- Desk legs (square or round extrusions)

- Edge trims and frame borders

- Cable trays and wire management channels

- Divider brackets and clamps

- Aluminum monitor arm bases

-

Storage Systems

- Cabinet posts

- Drawer rail brackets

- Heavy-duty shelf beams

- Glass or wood door frames

-

Partition / Panel Systems

- Vertical and horizontal panel frames

- Top/bottom trims

- Panel feet

- Aluminum clips and connectors

-

Doors and Glass Partition Systems

- Glass door frames

- Floor and ceiling frames

- Partition posts

- Edge trims and stabilizers

-

Office Chairs

Common in premium ergonomic chairs:

- aluminum 5-star bases

- aluminum armrest frames

- backrest structures

- Display and Retail Fixtures

- modular T-slot structures

- sign frames and lightbox frames

- shelving brackets

- Conference Room Furniture

- conference table frames

- acoustic panel frames

- projector rail tracks

Real Advantages of Aluminum Extrusion System Furniture

-

Long-Term Durability

- rust-free

- warp-free

- non-brittle

- 10–20+ year service life

-

Structural Strength

- high load capacity

- ideal for large desks, multi-monitor setups, wall panels

-

Expandable and Adjustable

- adjustable partitions

- extendable desktops

- additional cable systems

- movable furniture modules

-

Environmentally Friendly

Aluminum is 100% recyclable, meeting corporate ESG standards.

-

Consistent, High-End Aesthetics

Creates:

- tech ambience

- minimalist professional style

- unified corporate imagery

Aluminum Extrusion Is the Optimal Solution for OA System Office Furniture. Aluminum extrusions excel in durability, adjustability, aesthetics, installation efficiency, sustainability, and cost-effectiveness. Their precise manufacturing process and modular engineering make them suitable for long-term corporate use and future workspace reconfiguration.

For designers, architects, and contractors, aluminum extrusions offer unparalleled flexibility and customization. For business owners and procurement teams, they reduce long-term costs and provide a long-lasting asset. For users, they provide a stable, attractive, and safe working environment.

With Taiwan’s complete aluminum extrusion supply chain~from extrusion to machining and finishing~the quality and reliability of system furniture continue to rise. It’s no surprise that more companies prioritize aluminum-based system furniture when planning new offices.

If you need support with system furniture planning, mold development, co-extrusion, composite processing, or surface, or any aluminum-related processing, 【Yuan-Cheng Aluminum Co., Ltd.,】 in Tainan, Taiwan, is ready to assist you.

contact us