What Are the Processing Steps for Industrial Aluminum Extrusion 【Cabinet Brackets】?

Aluminum Extrusion 【Cabinet Brackets】 as the Core Components of Modern Industry and Furniture Manufacturing

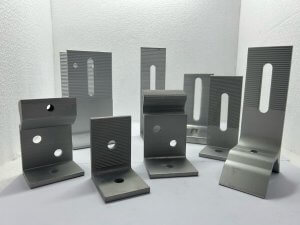

Aluminum extrusion materials are indispensable in modern industry and furniture design due to their lightweight, durable, corrosion-resistant, and highly malleable properties. Specifically, in applications such as 【Cabinet Brackets】, aluminum extrusion materials are favored for their outstanding structural strength, flexible design potential, and diverse processing options. Through precise manufacturing processes, 【Cabinet Brackets】 can meet various requirements ranging from residential to industrial applications while ensuring high standards in functionality, appearance, and longevity. This article will explain the characteristics of aluminum extrusion 【Cabinet Brackets】, key manufacturing steps, and their application advantages.

Structural and Material Properties of Aluminum Extrusion 【Cabinet Brackets】

Aluminum extrusion materials are the primary choice for 【Cabinet Brackets】 due to their lightweight structure and ease of processing. Their superior properties enable them to perform well in various applications. To understand their value, it is essential to grasp their core structural and material characteristics.

-

High Strength and Lightweight Design

One of the most significant advantages of aluminum extrusion materials is their combination of high strength and lightweight characteristics. The strength-to-weight ratio of aluminum alloys is much higher than that of traditional materials like iron or wood. This allows 【Cabinet Brackets】 to provide sufficient load-bearing capacity without adding unnecessary structural weight. For instance, in large industrial storage cabinets, lightweight brackets reduce installation and transport burdens while enhancing structural stability.

-

Superior Corrosion Resistance

Aluminum extrusion materials possess inherent oxidation resistance, but after surface treatments like anodizing or powder coating, their corrosion resistance improves significantly. This makes them highly effective in humid or high-salt environments. For example, 【Cabinet Brackets】 in kitchens, bathrooms, and other high-humidity spaces require superior corrosion resistance due to frequent exposure to moisture or chemicals.

-

Flexible Structural Design

Aluminum extrusion materials can be manufactured into different cross-sectional structures, ranging from simple rectangular, U-shaped, and T-shaped profiles to complex hollow designs. This design flexibility allows 【Cabinet Brackets】 to easily adapt to various assembly modes, whether for simple household cabinets or complex industrial equipment support. Additionally, modular designs enable quick part replacements and easier maintenance.

Key Processing Steps for Aluminum Extrusion 【Cabinet Brackets】

The manufacturing of aluminum extrusion 【Cabinet Brackets】 involves several key processing steps, from material formation to surface treatments, each influencing the product’s final quality and performance. Understanding these processes ensures that each step meets design requirements.

-

Aluminum Extrusion Formation (Extrusion Process)

The first step in the manufacturing of aluminum extrusion materials is the extrusion process. Heated aluminum billets are fed into an extrusion machine and pushed through a specific mold to create materials with the required cross-sectional shape. The mold design in this process directly determines the shape and structure of the bracket, so it must be precisely designed and crafted based on the product’s functional requirements.

- Mold-controlled cross-section shape: The mold must be designed according to the bracket’s functional needs, such as hollow structures for weight reduction or reinforcement ribs for increased load-bearing capacity.

- Temperature and pressure control: Extrusion temperature and pressure must be carefully controlled to ensure uniform material flow and avoid internal structural defects.

-

Mechanical Processing (Cutting, Drilling, and Assembly Hole Processing)

After extrusion, the materials undergo mechanical processing to meet specific application requirements. This step includes cutting, drilling, and other machining processes according to the design blueprint.

- Cutting and size adjustment: The materials are accurately cut to the required lengths based on cabinet size and installation needs, ensuring each bracket fits perfectly with the cabinet.

- Drilling and assembly hole processing: Holes or slots are created as needed for screws, hinges, and other fittings, enabling secure attachment to the cabinet.

- Precision machining: For high-precision structures or specialized brackets, additional CNC machining may be required to achieve high accuracy and detailed features.

-

Surface Treatments (Anodizing and Powder Coating)

To enhance the durability and aesthetic appeal of the brackets, aluminum extrusion materials typically undergo surface treatments after mechanical processing.

- Anodizing: An oxide layer is formed on the aluminum surface to improve corrosion resistance and offer various color options, giving the brackets an attractive finish.

- Powder coating: A layer of powder coating is applied to the material surface and cured under high temperatures, forming a durable protective layer that enhances scratch resistance and chemical protection.

- Anti-fingerprint treatment: For high-end or commercial 【Cabinet Brackets】, an additional anti-fingerprint treatment may be applied to improve the product’s surface texture and ease of cleaning.

Application Advantages and Versatile Use Cases for Aluminum Extrusion Cabinet Brackets

Aluminum extrusion 【Cabinet Brackets】 are not just structural supports; their diverse processing and design possibilities make them valuable across various industries. Below are the main advantages and application scenarios of these brackets.

-

Lightweight Structure with High Load Capacity

The lightweight nature of aluminum extrusion materials allows for reduced overall weight without compromising structural strength. This is crucial for cabinets that require frequent movement or adjustments, such as display racks and mobile storage cabinets. Additionally, their high load capacity ensures safe storage, even when heavy items are placed on the shelves.

- Household applications: Kitchen cabinets, wardrobe interior supports, and bathroom storage shelves.

- Commercial applications: Supermarket display racks and retail store counter supports.

- Industrial applications: Heavy-duty storage racks or equipment support structures in factories.

-

Durability and Longevity

Aluminum extrusion 【Cabinet Brackets】, after undergoing anodizing or powder coating, exhibit enhanced durability and resistance to environmental factors. In humid or corrosive environments, these materials maintain structural stability and aesthetic appeal for extended periods.

- Long-term corrosion resistance: Treated brackets can withstand prolonged exposure to high-humidity or chemically active environments without damage.

- Wear resistance: The surface remains resistant to wear and scratches even in frequent use or collisions.

-

Ease of Installation and Design Flexibility

Thanks to modular designs and standardized processing, aluminum extrusion brackets can be quickly installed and easily replaced. This reduces construction and maintenance costs in both industrial and household applications.

- Quick assembly: Most brackets can be assembled using pre-installed bolts or fasteners without the need for on-site welding.

- Customized designs: Depending on specific needs, brackets can be designed as detachable or fixed structures, offering flexibility across various applications.

Aluminum extrusion 【Cabinet Brackets】 are essential components in modern industrial, commercial, and household applications due to their excellent structural design, processing flexibility, and diverse applications. Whether for lightweight requirements, high load capacity, or flexible designs, they provide optimal solutions. For any inquiries regarding aluminum extrusion 【Cabinet Brackets】, please contact【Yuan-Cheng Aluminum Co., Ltd.,】for professional solutions and support.

contact us