Interior Decoration and Ceilings: Lightweight Aluminum Partition – Extrusion Manufacturer Recommended: YCAL!

In residential interior decoration, aluminum ceiling partitions, commercial office design, and public building planning, there is growing emphasis on lightweight structures, environmental sustainability, and construction efficiency. Among these, lightweight aluminum partition systems have become one of the most sought-after solutions in the market. Compared with traditional woodwork, brick walls, or steel frame partitions, aluminum extrusion structures offer multiple advantages such as durability, recyclability, refined appearance, and rapid installation. As a result, they are widely used in ceilings, interior partitions, lightweight walls, and office soundproof partition systems.

With the transformation and upgrading of the construction and renovation industries, more consumers and designers are inclined to adopt aluminum extrusion products. Among them, YCAL Yuan Cheng Aluminum, which focuses on aluminum extrusion development and applications, has become a key player in the decoration and partition market, backed by professional processing technology and comprehensive solutions.

Advantages of the Aluminum Processing Process

Flexible Alloy Selection

- Aluminum extrusion manufacturers generally use 6xxx series alloys (such as 6063 and 6061), combining strength, corrosion resistance, and workability.

- The alloy composition can be adjusted for different uses (interior decoration partitions, aluminum ceiling partitions, curtain walls, structural members), balancing cost and performance.

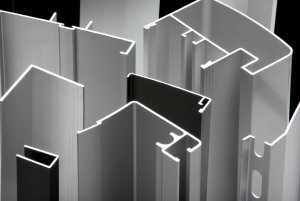

Diverse Extrusion Forming

- Through molds, complex cross-sections such as L-, T-, U-shaped, or hollow special profiles can be produced, fully meeting the needs of partitions and ceilings.

- High flexibility in mold design allows for “one-piece integration” of functions (cable channels, snap joints, pressure strips), saving subsequent processing steps.

Heat Treatment for Enhanced Durability

- After T5 or T6 heat treatment, the strength and hardness of aluminum can be significantly improved, avoiding deformation or fatigue common in ordinary metals.

- Suitable for long-term use in structural, suspended, or load-bearing areas, providing greater safety assurance.

Varied Surface Treatments

- Anodizing: Corrosion-resistant and scratch-proof, commonly used in office partitions and public spaces.

- Powder coating: Wide color options and strong weather resistance, ideal for Taiwan’s humid environment.

- Wood-grain transfer printing: Replaces natural wood, offering a natural look with durability and no risk of termite damage.

Standardized Quality Control

- The aluminum extrusion process can be highly automated, ensuring precise dimensions.

- Systematic inspection procedures (straightness, thickness, coating adhesion) reduce installation errors on site.

Seven Key Advantages of Aluminum Extrusions in Interior Decoration

Lightweight and Quick Installation

- Aluminum density is only about one-third that of steel, making transportation and installation easier and reducing labor intensity.

- Most construction uses dry installation methods, significantly shortening project duration while reducing dust, noise, and waste.

- Suitable for offices, residences, and hospitals where fast project timelines are critical.

Excellent Weather Resistance and Long Lifespan

- Naturally oxidation-resistant, and with anodizing or powder coating, aluminum can withstand Taiwan’s humidity and sea breeze.

- Resistant to deformation and corrosion, maintaining structural stability and appearance over time.

- Typical lifespan exceeds 20 years, far outperforming traditional woodwork and light steel framing.

Aesthetic and Versatile Styles

- Surfaces can be treated with anodizing, paint, or wood-grain transfer, creating metallic luster or natural wood effects.

- Wide color choices allow flexible design for modern minimalism, industrial style, or Japanese wood aesthetics.

- Aluminum grids for partitions and ceilings provide a clean, modern design aesthetic.

Easy Maintenance and Cleaning

- Aluminum does not mold, warp, or attract termites, unlike wood.

- Smooth surfaces require only a damp cloth for cleaning, resulting in very low maintenance costs.

- Ideal for medical institutions, schools, or office buildings that require long-term cleanliness.

Integrated Fire and Acoustic Performance

- Aluminum itself is non-combustible, and combined with fire-resistant boards can meet building code fire requirements.

- Aluminum partition frames can integrate double glazing, gypsum boards, or mineral fiber boards to improve sound insulation.

- Widely applied in meeting rooms, clinics, libraries, and other spaces requiring quiet and safety.

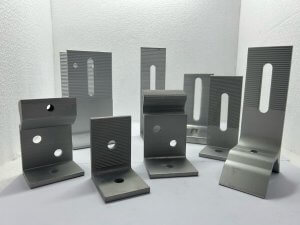

Modular and Reusable Design

- Aluminum partition systems adopt modular assembly, enabling fast dismantling and reuse.

- Perfect for rental offices or commercial spaces that frequently change layouts.

- Supports the circular economy by reducing waste and material consumption.

Convenient MEP Integration

- Aluminum partition systems can include built-in cable channels, concealing wiring and network lines neatly within the structure.

- Aluminum grid ceilings feature quick-release designs, allowing HVAC or fire system maintenance without large-scale removal.

- Greatly improves efficiency and convenience of long-term facility management.

Advantages of Aluminum Extrusions in Ceilings and Aluminum Partitions

Lightweight and Structurally Safe

- At only one-third the density of steel, aluminum is light yet maintains strong structural integrity.

- Suitable for high-rise buildings, old house renovations, or ceiling projects requiring reduced structural load.

- Reduces stress on hanging points, minimizing the risk of ceiling sagging or structural damage.

Fast Installation and Easy Maintenance

- Aluminum ceiling and partition systems are modular, ensuring fast installation and easy dismantling.

- Inspection panels allow quick access for HVAC, fire protection, and piping maintenance without large-scale removal.

- Particularly beneficial for offices, shopping malls, and hospitals that require uninterrupted operations.

Durability and Long Service Life

- Aluminum resists oxidation and corrosion; with anodizing or powder coating, it withstands humidity and salt damage.

- In Taiwan’s hot, rainy climate, it maintains long-term structural stability and appearance.

- Service life generally exceeds 20 years, far better than woodwork or standard light steel ceilings.

Aesthetic Variety and Design Flexibility

- Aluminum ceilings can be made in grid, linear, flat, or perforated acoustic panel designs.

- Surface finishes include metallic brushed textures, wood-grain transfer, matte black, pearl white, and champagne gold to match diverse styles.

- Partitions can be combined with glass, gypsum, or wood-grain aluminum panels to create bright or warm atmospheres.

Fire Safety and Acoustic Performance

- Aluminum is non-combustible; combined with fireproof coatings or resistant boards, it meets building flame-retardant standards.

- Ceiling grids can integrate acoustic cotton, while partition frames with double glazing or mineral boards improve soundproofing.

- Suitable for schools, hospitals, conference rooms, and hotels needing quiet and safety.

Environmentally Friendly and Reusable

- Aluminum partitions and ceilings can be dismantled and reused, ideal for rental offices or temporary exhibitions.

- Highly recyclable, aluminum complies with ESG and green building policies.

- Reduces demolition waste from wood or stone materials, lowering renovation costs and environmental impact.

Flexible Integration of Utilities and Lighting

- Aluminum ceiling systems with quick-release features allow easy repositioning of lighting, HVAC vents, and fire equipment.

- Partition frames with built-in wiring channels neatly conceal cables and wiring.

- Perfect for smart buildings or commercial spaces requiring frequent renovations.

In Taiwan’s interior decoration and ceiling markets, aluminum extrusions-with their superior properties, precise processing, and flexible applications-are gradually replacing traditional materials to become the first choice of designers and contractors. Among them, lightweight aluminum partition systems are the most widely used, balancing practicality and aesthetics while meeting modern spatial demands.

For customized mold development, co-extrusion with other materials, composite processing, or advanced surface finishing, Whether it is custom mold development, co-extrusion, composite processing, or surface treatment, please feel free to contact【Yuan-Cheng Aluminum Co., Ltd.,】 for professional service.

contact us