What Are Aluminum Profile Lightweight Partitions?

Whether it’s an apartment renovation in Taipei, an office remodel in Taichung, or a factory-space layout in Kaohsiung, aluminum profile lightweight partitions have quietly become a mainstream choice in interior design and construction. When people see aluminum frames combined with glass or wood-patterned panels, they are often impressed by the clean lines and modern look. However, what truly convinces professional engineers, site managers, and designers is not just the appearance~it’s the combination of stability, durability, and fast installation that aluminum profiles naturally provide.

In the past, partitions typically meant red brick, light steel framing, or woodwork. These traditional methods often required heavy masonry work, created dust, prolonged construction schedules, and were prone to issues like moisture, deformation, or high maintenance costs. Aluminum profile partitions have rapidly gained popularity in Taiwan because they perfectly meet the three major demands of modern interior renovation: aesthetic appeal, durability, and efficiency. Their corrosion resistance far surpasses wood and iron components, and the modular design allows panels to be removed, relocated, and reassembled without damaging the original structure. Whether for residential layout adjustments, open-plan office design, or factory partitioning, aluminum profile systems create practical and visually pleasing spaces quickly and cleanly.

So, what exactly are aluminum profile lightweight partitions? How is the cost per ping calculated? Are they worth choosing? From the perspective of real construction practices in Taiwan, this guide will help you understand their features, fabrication process, and actual advantages, so you can see why aluminum profile partitions have become a new standard in modern renovation.

What Are Aluminum Profile Lightweight Partitions?

As the name suggests, an aluminum profile lightweight partition uses aluminum extrusion profiles as the primary structural framework, combined with surface materials such as glass, acrylic, calcium silicate board, honeycomb board, or PVC board. These partitions are known for being lightweight, durable, and reconfigurable. They are widely used in office spaces, commercial interiors, factory areas, home studies, and rental unit layouts.

A typical aluminum profile partition consists of several main components:

-

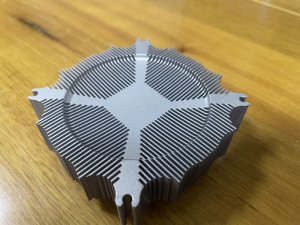

Aluminum Framework (Main Structural Support)

Made from 6063-T5 or T6 aluminum alloy, featuring high strength, corrosion resistance, and light weight. The surface is anodized and available in finishes such as matte silver, black sand, white, or champagne gold.

-

Panels (Surface Materials)

Depending on the requirement, panels can be clear or frosted glass, wood-patterned boards, calcium silicate panels, or lightweight PVC boards. Glass partitions provide brightness and openness, while solid boards enhance privacy and sound insulation.

-

Hardware and Sealing Components

Including connectors, trim pieces, rubber gaskets, and door locks, ensuring overall stability and aesthetics.

The greatest advantage of this system is its modularity~it can be assembled, adjusted, or dismantled according to the space layout. Installation typically takes only one-third of the time required for traditional masonry. With today’s emphasis on efficiency and flexibility, aluminum profile lightweight partitions are ubiquitous, especially in Taiwan’s urban areas where rental costs and space utilization are critical. They offer a balance of aesthetics and practicality unmatched by other methods.

Features and Fabrication of Aluminum Profile Lightweight Partitions

-

Material Characteristics

The core strengths of aluminum profiles are lightweight, strong, and stable. For example, 6063 aluminum alloy offers excellent workability and resistance to oxidation and corrosion~ideal for Taiwan’s humid and salty environments. Anodizing forms a protective oxide layer that improves scratch resistance, weather resistance, and appearance.

Aluminum is also more than 95% recyclable, making it one of the most eco-friendly building materials. Unlike steel or wood partitions, aluminum does not attract termites, warp, loosen, or mold over time—requiring minimal maintenance.

-

Fabrication Process

The manufacturing of aluminum extrusions involves several major steps:

- Melting and Extrusion

Aluminum billets are heated to around 500°C and pressed through mold dies to create specific profile shapes (U-shaped, T-shaped, square tube, round tube, etc.). These shapes become the structural frame of the partition. - Cooling and Cutting

Extruded profiles are rapidly cooled and cut to required lengths, typically 6 meters or custom sizes. - Anodizing and Surface Treatment

Anodizing ensures uniform color, wear resistance, corrosion resistance, and enhanced aesthetics. - CNC Precision Processing and Assembly

Profiles undergo CNC cutting, drilling, and tapping to ensure precise fit with panels and hardware.

-

Applications in the Taiwan Market

Aluminum profile lightweight partitions are widely used in:

- Tech factories and cleanrooms

- Corporate offices (glass partition systems)

- Clinics, fitness studios

- Rental units and old-building renovations

- Retail shops and commercial display zones

With the rise of “old house renovation,” many homeowners now prefer aluminum partitions because they allow reversible construction without damaging original structures and comply with regulations where lightweight partitions do not require building permit filings.

Advantages of Aluminum Profile Lightweight Partitions

-

Key Advantages

- Lightweight but High Strength

Aluminum is one-third the weight of steel, but T6-treated material can reach steel-like strength while remaining lightweight. - Fast Installation and Clean Construction

Modular design enables quick installation without heavy masonry or excessive noise; a 10-ping space can often be completed in 1–2 days. - Modern Look and Clean Lines

Aluminum frames paired with glass or board panels create styles ranging from Japanese minimalism to Scandinavian and industrial chic. - Reusable and Eco-Friendly

The system can be dismantled and reassembled, minimizing waste. - Excellent Weather Resistance and Dimensional Stability

Ideal for southern or coastal Taiwan, resisting humidity, heat, and rust. - Integrated Wiring and Acoustics Options

Wiring can pass through the aluminum framework, keeping surfaces clean. Sound insulation can be enhanced with calcium silicate board or acoustic materials.

-

Suitable Spaces

- Homes: studies, bedrooms, living room partitions

- Commercial areas: offices, meeting rooms, showrooms

- Industrial facilities: cleanrooms, inspection rooms, machinery zones

- Rental units: studio suites, co-living spaces, short-term rentals

-

Usage Tips and Maintenance

- Clean the aluminum surface with neutral detergents to avoid corrosion.

- Use safety glass or anti-shatter film for glass partitions.

- Have professionals handle assembly/disassembly to avoid structural damage.

- For outdoor or semi-outdoor use, powder coating or fluorocarbon coating is recommended for longevity.

How Is the Cost per Ping Determined?

Many people ask, “How much does a lightweight partition cost per ping?”

There is no fixed rate because pricing depends on multiple factors. Understanding these factors is far more meaningful than simply quoting a number.

Key Factors that Determine the Cost:

-

Aluminum Profile Specifications

Profiles vary by thickness, grade, and structural strength. Higher-grade profiles naturally affect the overall cost.

-

Panel Material

Choices include:

- Clear glass

- Frosted glass

- Wood-patterned panels / calcium silicate boards

- Acrylic / PC hollow boards

- High-performance composite panels

More advanced materials correspond to higher unit cost.

-

Performance Requirements

Extra functions such as:

- Soundproofing

- Fire resistance

- Impact resistance

- Air-tightness

- Cleanroom-level sealing

These require more complex construction and materials.

-

Site Conditions

Factors include ceiling height, integration with doors, concealed wiring, column wraps, vertical installation feasibility, delivery distance, and material handling difficulty.

-

Design Complexity

Curved profiles, multiple corner transitions, mixed materials, custom colors, and full-height glass panels will influence the final cost.

Why Aluminum Profile Lightweight Partitions Have Become Mainstream

Their popularity stems from more than good aesthetics~they solve long-standing issues in traditional partition construction. Aluminum does not warp, rust, or swell from moisture. It can be dismantled and reassembled, installed quickly, and maintains an excellent visual finish. Whether you’re a homeowner, designer, contractor, or factory manager, aluminum profile partitions provide a reliable and practical solution.

For residential spaces, they offer flexible living arrangements, enabling reconfiguration without structural damage.

For offices and commercial spaces, they provide efficiency, branding appeal, and durability.

For factories and professional environments, they ensure weather resistance, structural stability, and expandability.Whether you need custom development, co-extrusion, composite processing, or surface finishing, feel free to contact【Yuan-Cheng Aluminum Co., Ltd.,】 in Tainan, Taiwan for assistance.

They specialize in aluminum extrusion design, lightweight partition systems, custom fabrication, and on-site engineering evaluation~ensuring your space achieves higher quality, durability, and functionality.

contact us