What Are the Specifications and Accessories of Architectural Aluminum Extrusions for Curtain Systems?

Introduction: Curtain Aluminum Extrusions – A Critical Element in Modern Architecture.As architectural design in Taiwan shifts toward modern and minimalist aesthetics, curtain systems are no longer just tools for shading—they are now a fusion of spatial beauty and functionality. In this context, aluminum extrusions for curtain systems have become essential structural components in building design. Whether for residential homes, commercial offices, performance venues, or high-rise curtain walls, aluminum extrusions are widely used to support and guide curtain systems due to their lightweight properties, corrosion resistance, sleek appearance, and high formability.

When selecting and installing aluminum extrusions, stakeholders—including developers and designers—are particularly concerned about specifications, available accessories, manufacturing processes, and overall cost. Understanding these factors in advance not only enhances construction efficiency but also reduces maintenance costs, ultimately improving the building’s quality and lifespan. This article explores the current aluminum extrusion industry in Taiwan, with a special focus on aluminum extrusions for curtain systems, providing a comprehensive guide for designers, contractors, and consumers.

Specifications and Applications of Curtain Aluminum Extrusions: The Backbone Behind Elegant Interiors

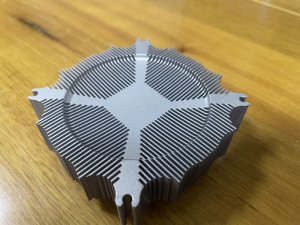

Before diving into aluminum extrusions for curtain systems, it’s essential to understand what aluminum extrusion is. The process involves heating aluminum alloy to a specific temperature and pushing it through a die to form various cross-sectional shapes. This technique allows the creation of complex profiles that are lightweight yet structurally strong.

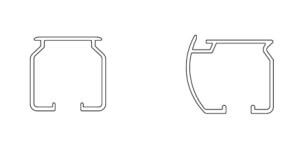

Several standard extrusion types are commonly used for curtain systems:

-

Single-track aluminum rails – Ideal for homes and small offices, simple in structure and easy to install.

-

Double-track rails – Enable dual-layer curtains (e.g., sheer and blackout curtains) for added versatility.

-

Box-type rails – Common in concealed installations for a cleaner, modern aesthetic.

-

Industrial-grade extrusions – Used for large-scale venues requiring strong support for extended spans.

-

Curved extrusions – Offer design flexibility for arched windows or architectural features.

Standard lengths often include 1.5m, 2m, and 3m options, with thicknesses ranging from 1.0mm to 2.5mm, depending on load-bearing requirements. Excessive thickness can drive up costs, while insufficient thickness may compromise stability.

In Taiwan, curtain aluminum extrusion options are abundant. They cater to different aesthetic and functional needs in residential and commercial projects. Due to their high standardization, extrusions can easily integrate with a wide range of curtain accessories. Additionally, surface treatments such as powder coating or anodizing enhance durability and visual appeal, ensuring they blend seamlessly with modern interior themes.

Accessories and Installation Methods: Elevating User Experience Through Functional Design

While aluminum extrusions form the structural base, their actual functionality relies heavily on complementary accessories. The main accessories used with aluminum extrusions for curtain systems include:

-

Gliders or rollers – These allow smooth curtain movement along the track and are typically made from low-friction, wear-resistant materials like PA or POM.

-

Stoppers – Prevent over-travel or detachment of the curtain gliders.

-

Mounting brackets – Secure the extrusion to the wall or ceiling, available in surface-mount or recessed configurations.

-

End caps and decorative covers – Provide a clean finish and prevent sharp edges from being exposed.

-

Pull cords and control systems – For manual operation, some systems incorporate gears and pulley mechanisms.

Installation methods generally fall into three categories:

-

Surface-mounted: The track is exposed, offering easy access for maintenance; cost-effective.

-

Recessed installation: The track is concealed within a ceiling groove or cavity, enhancing visual cleanliness.

-

Embedded installation: Often used in coordinated woodwork or framing systems; requires pre-planned structural design.

Many premium commercial environments are now adopting motorized curtain systems. In such cases, the extrusion must accommodate motor rails, smart controllers, and remote switches. These may even be integrated with smart home platforms like Google Home or Apple HomeKit for voice-activated or automated operation.

Although the extrusion may appear simple, it integrates mechanical design logic and precision machining to deliver a smooth and reliable curtain system.

Manufacturing Process and Material Advantages: From Raw Aluminum to Finished Extrusions

Understanding the manufacturing process of aluminum extrusions for curtain systems is vital to appreciating their quality, performance, and pricing.

The general production flow includes:

- Billet preparation and heating – Common alloys like 6063 or 6061 are heated to 480–520°C to soften the material for extrusion.

- Extrusion – Heated billets are pushed through dies to form specific cross-sections.

- Cooling and stretching – Rapid cooling followed by mechanical stretching eliminates internal stress and maintains straightness.

- Cutting and straightening – Profiles are cut to custom lengths and adjusted for dimensional accuracy.

- Surface finishing:

- Anodizing: Enhances corrosion resistance and provides a matte or satin finish.

- Powder coating: Offers a wide range of color options and increased UV resistance.

- Quality inspection and packaging – Final checks are conducted to ensure surface smoothness, dimensional accuracy, and color uniformity.

Key benefits of aluminum extrusions include:

- Lightweight yet strong – Offers structural performance without the added weight.

- Dimensional stability – Reduced internal stress enhances long-term reliability.

- Excellent corrosion resistance – Especially when paired with anodized or coated surfaces.

- Highly customizable appearance – Extrusions can be tailored to match a variety of interior styles.

- Sustainability – Aluminum is 100% recyclable, aligning with environmental goals.

These features make aluminum extrusions not just practical construction materials but also essential design elements.

Aluminum Extrusions Combine Aesthetics and Functionality in Curtain Systems.Aluminum extrusions for curtain systems are crucial components in modern building environments. They serve as the backbone of curtain infrastructure, combining functionality with design elegance. From cross-sectional design and accessory integration to surface finishing and cost calculation, the complexity behind these components reflects the precision and planning required for high-quality construction.

Choosing a trustworthy supplier with expertise in aluminum extrusion ensures optimal product performance and long-term satisfaction. If you’re working on product design, equipment development, or architectural planning and need support for custom dies, co-extrusion, hybrid processing, or surface treatments, don’t hesitate to contact 【Yuan-Cheng Aluminum Co., Ltd.,】 for professional advice and customized services.

contact us