Exterior Aluminum Louver/Slat Fencing – Materials, Styles & Sizes Guide

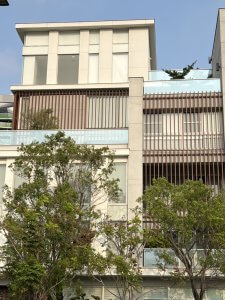

In recent years, residential and commercial architecture in Taiwan has shifted toward sleek, minimalist aesthetics. Whether you walk down city streets, pass new housing projects, explore gated communities, or visit coastal villas, you’ll notice one growing trend ~ more and more buildings are replacing traditional iron and concrete fences with aluminum louvers.

Why is aluminum becoming the top choice?

It’s not just about modern looks ~ aluminum louvers meet the three major needs of today’s architecture: durability, weather resistance, and visual appeal.

Taiwan’s island climate brings humidity, strong UV exposure, high rainfall, and coastal salt corrosion. Traditional materials rust, warp, crack, or rot over time, while aluminum remains rust-free, lightweight, and fully customizable in size and shape — making it the most popular option among developers, designers, and homeowners.

What makes aluminum louvers so versatile isn’t just the material. They can be designed horizontally or vertically, as flat or 3D elements, and customized in spacing, width, colors, and surface finishes. From private homes to retail stores, from factories to public spaces, aluminum louvers can be adapted to virtually any architectural style.

Below, we’ll break down aluminum louver applications, material characteristics, fabrication processes, and selection tips — so you’ll know exactly how to plan your new build or renovation.

Where are Aluminum Louvers Used?

Because they are stylish, lightweight, and long-lasting, aluminum louvers are used almost everywhere ~indoors and outdoors:

-

Architectural Exterior Facades

- Residential homes, apartment towers, commercial buildings

• Sun-shading without blocking airflow or views

• Horizontal or vertical installation options

• Adds shadow depth and visual rhythm to facades

-

Perimeter Fencing & Courtyard Walls

- Private house boundary walls or gated communities

• Provides privacy while maintaining ventilation and daylight

• Strong visual upgrade over concrete walls or iron fencing

-

Balconies, Terraces & Parapet Walls

- Enhances edge protection and safety

• Privacy screening without closing the space

• More durable and lower maintenance than glass railing

-

Garage Screens & Driveway Gates

- Stylish garage frontage design

• Improves ventilation for enclosed garage spaces

• Hides clutter while maintaining an open look

-

Commercial & Public Installations

- Shopping malls, storefront branding facades

• Schools, parks, transport hubs

• Decorative louvers for architectural lighting and art

-

Factory & Industrial Buildings

- Adds visual warmth to rigid steel structures

• Screens mechanical equipment and storage

• Can incorporate corporate colors or logo shapes

-

Interior Design Applications

- Ceiling louvers

• Sliding or semi-transparent partition walls

• Daylight ceilings, greenery wall structures

Key Characteristics of Aluminum Louvers

-

Rust-Free & Highly Weather Resistant

Perfect for Taiwan’s:

• Humid north

• Salt-laden coastal regions

The natural oxide layer protects aluminum — unlike steel that rusts or wood that rots.

-

Lightweight & Safe

Approximately one-third the weight of steel

• Reduces load on structure

• Ideal for high-rise buildings or old-house renovations

-

Strong & Long-Lasting

Use of 6000 series aluminum alloy (T5/T6) offers:

• Excellent bending resistance

• Structural stability

• Service life of 10–20+ years

-

Extremely Flexible to Process

Cutting, bending, drilling, welding, and custom forming

— Any design concept can be achieved.

-

Wide Range of Colors & Finishes

Most common finishes:

• Powder coating (matte black/gray/white/brown)

• Anodizing (durable metallic finish)

• Wood-grain transfer printing (teak, cypress, oak)

-

Minimal Maintenance

Simply wash off dust

No annual repainting like wood

Ideal for modern low-maintenance living

Common Sizes & Specifications

There is no universal standard size — all dimensions depend on design intent and site requirements.

-

Louver Width (Primary Visual Element)

Common options:

• 20mm

• 25mm

• 38mm

• 50mm

• 75mm

• 100mm

Wider bars are often used on commercial facades.

-

Thickness (Safety Matters)

- 1.2mm

• 1.5mm

• 2.0mm

For outdoor installations, 1.5mm+ is recommended; high-wind zones may require 2.0mm.

-

Spacing (Controls Privacy & Ventilation)

- 5mm — near solid look, maximum privacy

• 10mm — most common for homes, balanced effect

• 15–20mm — more open, architectural expression

-

Length

- Standard extruded stock length: 6 meters

• Cut to size on-site

-

Cross-Section Profiles

- Square tubing

• Flat bar

• Channel profiles

• Ribbed or 3D forms

• Customized branding shapes

Custom extrusion molds allow limitless profile options

Why Aluminum Louvers are Ideal for Exterior Walls

Aluminum combines the durability of metal with the warmth of wood-like aesthetics.

-

No Rust, No Rot

Typical exterior failures:

• Steel rusts

• Wood cracks, warps, molds, attracts insects

• Concrete absorbs moisture and stains

Aluminum’s corrosion resistance reduces long-term maintenance.

-

Lightweight Structure = Lower Risk

Less load on:

• Wall framing

• Bolts and fasteners

• Earthquake stress

Perfect for retrofits and expansions.

-

Highly Customizable & Visually Appealing

Profiles, spacing, and finishes can create:

• Industrial look

• Natural wood appearance

• Japanese minimalism

• Retail branding power

Aluminum Louver Fabrication Process — From Raw Metal to Structure

Many assume louvers are simply assembled metal bars.

In reality, the process is systematic:

-

Alloy Selection

Most high-quality louvers use 6000 series aluminum

• 6063-T5/T6 for corrosion resistance and formability

-

Extrusion

Aluminum is heated and pushed through extrusion dies

to form consistent cross-sections:

• Square tubes

• Flat slats

• Channels

• Ribbon louvers

• Custom industrial shapes

-

Surface Treatment

- Powder coating

• Anodizing

• Wood-grain transfer

Advanced pre-treatment needed in coastal regions.

-

Precision Cutting, Drilling & Assembly

- CNC cutting

• Accurate hole placement

• Welded or mechanical fastening

-

On-Site Installation

With:

• Base plates

• Chemical anchors

• Aluminum beams and posts

Proper installation ensures louvers remain aligned and secure, even in strong winds.

How to Choose Aluminum Louvers for Exterior Fencing

Horizontal Louvers

- Sleek, modern look

• Extends visual width

• Adjustable spacing

Common for residential fences and commercial walls

Vertical Louvers

- Enhances height and architectural lines

• Great for tall walls or public facades

• Works exceptionally well with lighting

Custom & 3D Louvers

- Diamond and wave patterns

• Interlocked geometries

• Logo-shaped louvers

• Mixed perforated panels and louvers

Ideal for branding or iconic building identity

The rapid adoption of aluminum louvers in Taiwan’s construction industry is no coincidence.

They solve the long-standing issues of traditional materials — wood decays, steel rusts, and concrete visually blocks and weighs down a structure.

Aluminum is the ideal balance:

• Lightweight

• Durable

• Stylish

• Easy to install

• Customizable to any architectural theme

It fits perfectly into new builds, renovations, homes, apartment blocks, factories, and commercial buildings. With adjustable spacing, louvers provide privacy without sacrificing air, light, or aesthetics — making them one of the most practical and visually enduring materials available today.

If you are considering aluminum louvers for exterior walls, perimeter fencing, facade upgrades, or community improvements — and require professional design, engineering assessment, material selection, extrusion molds, or finishing options —contact 【Yuan-Cheng Aluminum Co., Ltd.,】 in Tainan, Taiwan for expert support.

From material sourcing and extrusion to fabrication and installation, the team ensures your project achieves durability, quality, and architectural beauty.

contact us